Are Rigid Boxes Expensive?

Depending on the materials used, the size, the design, and the finish rigid boxes can indeed become quite expensive. This is usually why rigid boxes packaging is usually used for high-quality products, while most products targeting the bottom-line use regular packaging.

But, rigid boxes don’t always have to cost an arm and a leg, however. And here at Art of Packaging, we use advanced manufacturing and organizational methods to cut down costs and make custom rigid boxes affordable. So, if you’re interested in making your product appear high-end with the help of luxury rigid boxes, then give us a call.

How Do You Make a Rigid Box?

Although the process of building a rigid box can vary from one company to another, they all generally follow the same outline:

- Sizing: custom rigid boxes come in a lot of different sizes. The first step we take is making sure the paperboard is the correct size for our client’s product.

- Folding: after the paperboard is the proper size, it is then folded to give it the basic shape of the box. Only after the basic shape of the box is finalized can the other steps on the list be carried out.

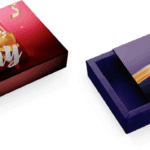

- Printing the design: after the basic shape of the rigid box is ready, the design is including the embellishments, the foils, the embroidery, the trinkets and more is superimposed on top of the basic shape of the box.

- Wrapping: whether this is done at your company or ours, the wrapping is the final piece of the puzzle and makes the rigid box complete and ready for consumer shelves.

This is the basic outline of how a manufacturer makes a rigid box.

Are Rigid Boxes Recyclable?

Rigid boxes’ recyclability, like all other products, depends on the materials used in making the boxes. Although some companies use synthetic materials that are hard to reuse and take a long time to break down by the environment, the materials we use to make our rigid boxes are almost completely biodegradable. This is a huge plus for people worried about the environmental impact of your products.

Rigid Boxes are Suitable for Which Types of Products?

There’s a short and long answer: the short answer is rigid boxes are suitable for all kinds of products.

The long answer is that rigid boxes do come with a price premium, and they’re indeed not suitable for products above a certain size, so this does limit their uses somewhat. Typically, if you want your products to make a good first impression, going with luxury rigid boxes is a good investment that can easily help you make extra profit.